Access to clean and sanitary water every day is a need for every one of us. Our demand for water has been rising for a long time. The more products we produce, manufacture, consume and discard, the more water we use. Reducing water waste and water pollution is our common responsibility, improving the efficiency of wastewater treatment, and achieving a clean water cycle is our direction of effort.

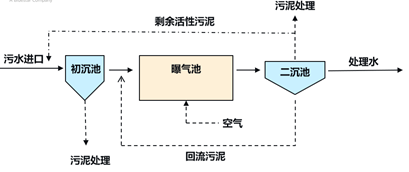

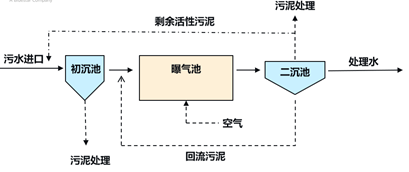

Industrial sewage contains high content of organic pollutants, heavy metals, pathogenic microorganisms and other substances, so it is necessary to carry out tertiary wastewater treatment, which generally uses three processes: physical treatment, chemical treatment and biological treatment

In the aeration tank, because the air is blown out from the inside of the aeration tank, in addition, the microorganisms in the activated sludge will produce gas in the process of decomposing organic matter, so a large amount of foam will be produced in the interior and surface of the sewage in the aeration tank.

These foams will continue to accumulate on the surface and have a serious impact on the entire water treatment process, such as:

Excessive foam reduces the water storage capacity of the aeration tank and reduces the efficiency

Foam affects the treatment efficiency of activated sludge by microorganisms

Foam carried to the next process affects secondary precipitation resulting in overflow, which in turn causes further pollution.

Therefore, the foam needs to be controlled and eliminated in the aeration tank!

advantage

Silicone defoamer proved to be the most ideal material for this process!

High defoaming efficiency of silicone defoamer

The physiological inertia of silicone materials will not cause negative harm to microorganisms

Compared with other kinds of defoamer, silicone has lower BOD and COD consumption, and the addition of silicone defoamer has the least effect on the increase of BOD and COD

The wide range of application of silicone defoamer makes it have excellent defoamer performance in different environments.

Silicone A range of defoamer products developed using non-toxic and chemically inert silicone raw materials to address the challenges posed by foam in wastewater treatment and water recycling. Silicone defoamer not only has fast defoaming performance, but also has excellent lasting defoaming ability. It not only ensures that the production process is more efficient and cleaner, but also improves the quality of the customer's final product, reduces waste and energy consumption and promotes recycling.

Advantages of foam control agents include:

In all stages of water purification process can play a lasting foam control role;

In the case of very little dosage can also play a high efficiency bubble control performance;

Help water treatment plants improve process reliability;

It exhibits excellent dispersion properties in water-based media, so it is very easy to use;

Suitable for a variety of industrial media and a wide range of pH values;

Chemical oxygen demand (COD) is very low, very environmentally friendly;

Long-term storage stability.