Study on high temperature resistant silicone / epoxy resin powder coating for automobile exhaust pipe

2.5 effect of silane coupling agent on coating performance

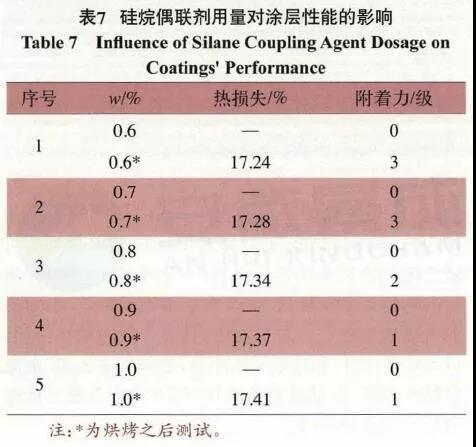

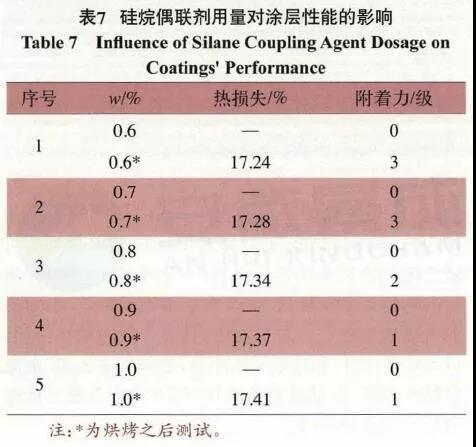

Silane coupling agent can increase the adhesion between the coating and the substrate, also can increase the adhesion between materials, thus improving the overall performance of the coating. The effect of different silane coupling agent dosage on the coating performance is shown in Table 7.

According to table 7, the adhesion of the coating increases with the increase of the dosage. When the dosage is greater than 0.9%, the adhesion of the coating will not increase any more, so the dosage selected for the next experiment is 0.9% (mass fraction).

2.6 effect of leveling agent dosage on coating performance

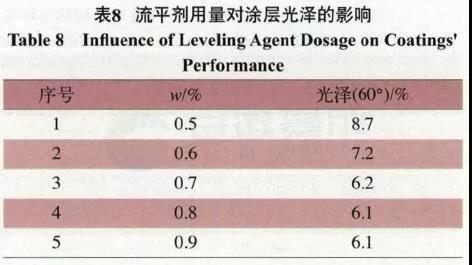

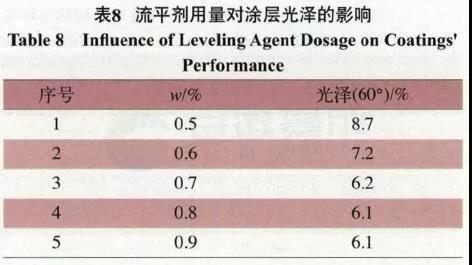

Because the epoxy resin is added into the powder coating system, the compatibility between the epoxy resin and the silicone resin is low, the sand grain formed has bright spots, the gloss of the coating is increased, and the decoration of the coating is reduced. Therefore, a small amount of leveling agent should be added to reduce the bright spot and improve the decoration of the coating. However, the loss of leveling agent at high temperature should not be too much, so as not to reduce the mechanical properties of the coating. The influence of the amount of leveling agent on the gloss of the coating is shown in Table 8.

It can be seen from table 8 that with the increase of leveling agent dosage, the gloss will gradually decrease; when the dosage is greater than 0.7%, the gloss of the coating will not decrease any more and the bright spots will disappear. Therefore, the selected dosage of leveling agent is 0.7% (mass fraction).

3 conclusion

(1) a kind of high temperature resistant powder coating, which can withstand 600 ℃ high temperature for 1 h, was successfully prepared by using silicone resin with epoxy resin and high temperature resistant pigments and fillers. The coating has good mechanical properties and is completely suitable for the use of automobile exhaust pipe.

(2) through the above experiments, it can be concluded that silica powder as filler has the best high temperature resistance and the least influence on the color difference and heat loss of the coating: Ferromanganese black is selected as black pigment; the dosage of silicone resin and epoxy resin is fixed at 45% (mass fraction) and 15% (mass fraction); the dosage of boronic glass powder is 10% (mass fraction); the dosage of talcum powder is 3% (mass fraction) Fraction: the dosage of silane coupling agent is 0.9% (mass fraction); the dosage of leveling agent is 0.7% (mass fraction).

Wen / LV Ying 1, bu Qingpeng 2, Wang Xiaoqiang 2, pan Jianliang 2